Overcome difficult Black Liquor level measurements in Paper & Pulp

APT 3100 Overcome difficult Black Liquor level measurements in Paper & Pulp production!

Black liquor is the waste liquor from the pulping process after pulping is completed. It contains most of the original cooking inorganic elements and the degraded, dissolved wood substance. The latter includes acetic acid, formic acid, numerous other carboxylic acids (all as the sodium salts), dissolved hemicelluloses, methanol, and hundreds of other components. It is an extremely complex mixture. The black liquor must be concentrated to as high a solids content as possible before being burned in the recovery boiler.

Black liquor offers some unique measurement challenges. It is a highly alkaline material that varies in density, depending on what is happening upstream. Black liquor must undergo several processing stages before the cooking liquor is reclaimed. Containment of the spent liquor must be measured and controlled in a series of intermediate storage tanks. To add to the challenge, the black Liquor is sticky, and coats surfaces easily.

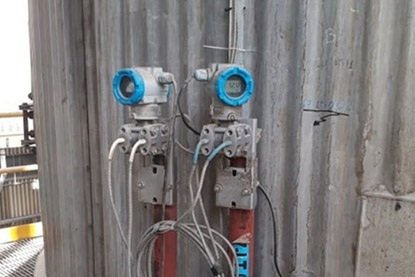

The Autrol APT3100 pressure transmitters are used to measure the black liquor level. It has proven to be a reliable measurement for the liquid level no matter what stage the Black Liquor is in. The process temperature of black liquor is typically 300 degrees F, so diaphragm seals are used to isolate the transmitter.